The Otto engine is a type of reciprocating heat engine that works through the Otto cycle. It is an alternative engine capable of converting the chemical energy of the fuel into mechanical energy by means of a thermodynamic reaction.

Due to the characteristics of this type of heat engine, it can receive various names.

- Gasoline engine. Due to the fuel used.

- Otto engine. Because it works through the Otto cycle.

- Spark ignition engine. Due to the way the fuel ignites. Ignition is initiated through a gust generated by a spark plug.

What are Otto engines used for?

Most motorsport engines belong to the Otto engine category (gasoline engine or positive ignition engine). Although in recent years the diesel engine has also become very popular. A large part of the engines for industrial traction, all the engines for motorcycles and aircraft and a good part of the engines for marine and agricultural applications use the Otto cycle.

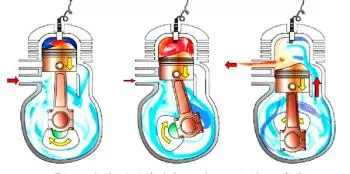

The Otto engine can run in 4-stroke or 2-stroke cycles. However, the 2-stroke Otto cycle is little used because of the loss of mixture that occurs through the exhaust and the consequent high fuel consumption.

Therefore, the vast majority of Otto engines operate according to the 4-stroke operating cycle. The 2-stroke spark ignition engine is adopted only in particular cases, such as outboards and small motorcycle engines.

What is the fuel that an Otto engine uses?

The fuel for an Otto engine is gasoline. Gasoline is made up of light hydrocarbons with a high calorific value, which evaporate easily. Gasoline is obtained from petroleum, a fossil fuel that is extracted from the ground.

The Otto engine can also use gaseous fuels or liquefied gas as well, but its use is less practical and therefore much less widespread.

Gasoline is obtained from crude oil in a refinery. In general, it is obtained from direct distillation naphtha, which is the lightest liquid fraction of petroleum (except for gases). Naphtha is also obtained from the conversion of heavy fractions of oil (vacuum gas oil) in process units called FCC (fluidized catalytic cracking) or hydrocracking.

A series of specifications required for the engine to function well and others of an environmental nature must be met, both regulated by law in most countries. The most characteristic specification is the octane number, which indicates its tendency to detonate.

There are different types of commercial gasoline, classified according to their octane number.

Otto motor power

Otto engines can be fueled by carburetion or injection. In Otto injection-fed engines, gasoline is mixed with air by injecting it into the intake duct at the valve intake, or directly into the combustion chamber. Among the two methods of laminating fuel, the most widely used is fueled by carburization.

The injection feed of the Otto engine, in the case of multi-cylinder engines, has the following advantages:

- It distributes the fuel evenly in the various cylinders.

- Not sensitive to acceleration

- It is not subject to ice formations.

On the contrary, this type of fuel supply of the gasoline engine has the following disadvantages that it is more complicated and expensive, especially with regard to regulation.

What is the cycle of a gasoline engine?

The gasoline engine is governed by the so-called Otto cycle or Beau de Rochas cycle.

The Otto cycle is the ideal thermodynamic cycle that is applied in provoked ignition internal combustion engines (gasoline engines). It is characterized by the fact that, in a first theoretical approximation, all the heat is supplied at a constant volume.

Otto cycle efficiency

The efficiency or thermal performance of an engine of this type depends on the compression ratio, the ratio between the maximum and minimum volumes of the combustion chamber. This ratio is usually 8 to 1 to 10 to 1 in most modern Otto engines. Higher ratios such as 12 to 1 can be used, thus increasing engine efficiency, but this design requires the use of high octane fuels to avoid detonation.

A low compression ratio does not require a high octane fuel to avoid this phenomenon, in the same way, a high compression requires a high octane fuel, to avoid the effects of detonation, that is, auto-ignition occurs. before producing the spark at the spark plug. The average performance of a good Otto 4-stroke engine is 25 to 30%, lower than the performance achieved with a diesel engine. Diesel engines reach efficiencies of 30 to 45%, precisely due to their higher compression ratio.

Otto engine history

The spark ignition engine was invented, practically in parallel, by two different inventors: Alphonse Beau de Rochas and Nikolaus August Otto.

The first inventor of the Otto engine, around 1862, was the Frenchman Alphonse Beau de Rochas. The second, around 1875, was the German doctor Nikolaus August Otto. Since neither of them knew of the other's patent until engines were made in both countries, there was a lawsuit. Eventually, De Rochas won a certain sum of money, but Otto kept the fame and the name.

The thermodynamic principle of the four-stroke engine is still called the Otto cycle.

Otto built his engine in 1866 together with his compatriot Eugen Langen. It was a gas engine that soon after gave rise to the four-stroke internal combustion engine. Otto developed this machine in four- and two-stroke versions. Later, this machine would bear his name: Otto cyclic engine.