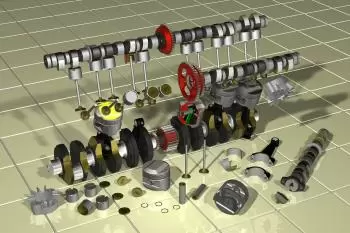

In this section we describe the different parts of a heat engine. Thermal engines have many types, however we will focus on the diesel engine and the gasoline engine (Otto cycle).

Despite being different engines they share many parts in common, so the presented scheme will serve to indicate the nomenclature of each element.

The most important elements of internal combustion engines, common to diesel and explosion engines, are classified into two main groups:

- Fixed elements of a thermal engine: block, cylinder head, crankcase.

- Moving elements of a thermal engine: piston, connecting rod, crankshaft and flywheel.

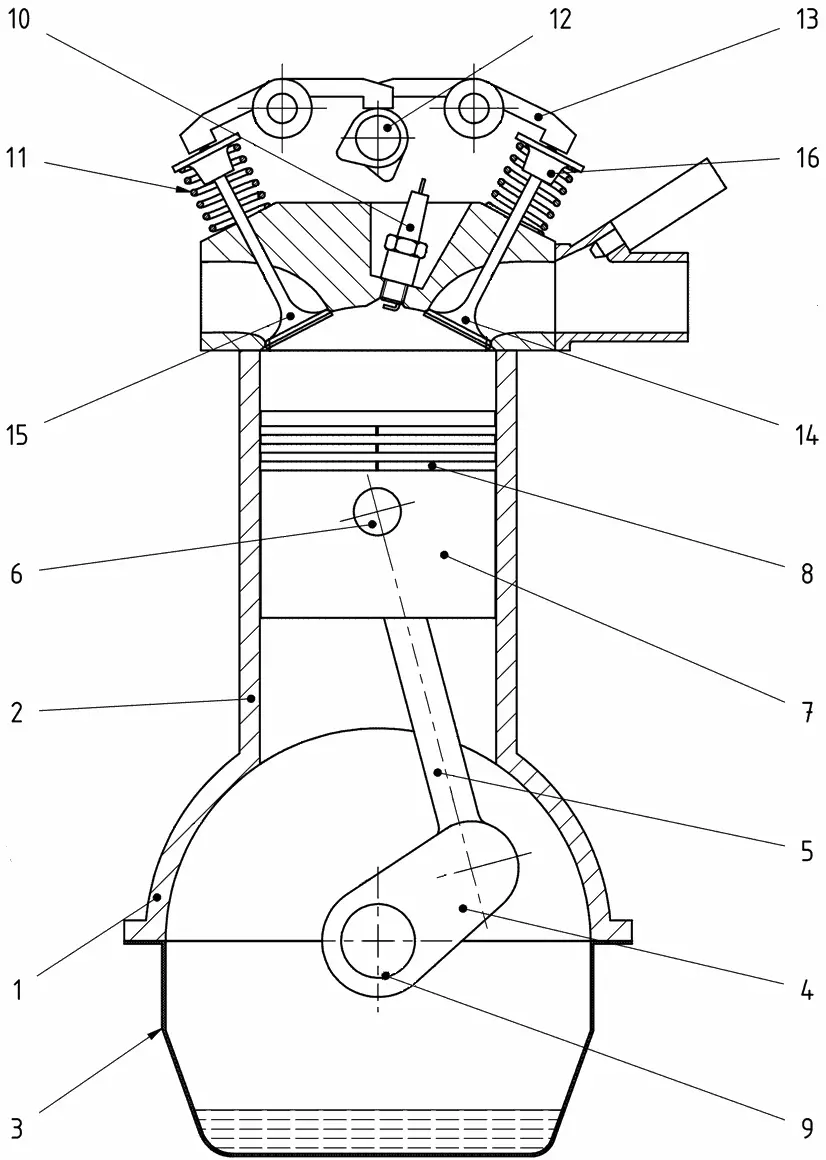

1.- The bench.

2.- The cylinder.

3.- Tray, oil tank

4.- The crankshaft.

5.- Connecting rod

6.- Plunger

pin 7.- The piston.

8.- Compression rings

9.- Crankshaft

10.- The spark plug.

11.- Valve spring

12.- Camshaft

13.- Rocker

14.- Exhaust

valve 15.- Suction valve

16.- Valve head

The cylinder is the container in a cylindrical shape in which the piston moves with an alternative rectilinear movement. The cylinder is part of the cylinder block or monoblock, as it was formerly called. This, in turn, is part of the bedplate, which we can consider as the fundamental structure of the engine. In many cases, the cylinder block is separated from the bed, to which it is connected by bolts.

The upper part of the cylinder is closed by the cylinder head.

The volume in the cylinder between the cylinder head and the piston represents the combustion chamber, in which the mixture of air and fuel is burned, that is, the active fluid.

What are the fixed elements of a heat engine?

Engine block

The block is the element that contains the cylinders. Inside the engine block are the driving elements (pistons, connecting rods and crankshaft), which serves as a support or bench. It is generally made of gray cast iron (iron alloy with a carbon content ranging from 2 to 4.5%) or aluminum alloy. The shape and dimensions depend on the number and arrangement of the cylinders.

Outside the block the rest of the construction elements of the thermal engine are fixed: the cylinder head at the top and the crankcase at the bottom. At one end are located the control elements of the distribution and the auxiliary organs of the engine, such as the alternator, the air conditioning compressor, etc., and at the opposite end is the gearbox.

In the block there are also the elements for anchoring the engine to the chassis, supports that have elastic elements to absorb engine vibrations, thus preventing them from being transmitted to the body.

Engine cylinders

Cylinders are the most important part of the block. Inside the cylinder the piston moves between the extreme positions (upper dead center PMS and lower dead center PMI) that it occupies during its reciprocating movement.

In the case of the gasoline engine (Otto cycle) the presence of the spark plug is necessary. In this case, the spark plug will be in charge of generating a spark inside the cylinder to start the ignition of the fuel, in this case, gasoline.

According to the procedure used to obtain the cylinders, we distinguish three types of block:

- Integral block: The cylinders are machined on the material of the same block.

- Dry liner block: In this case, a thin-walled cylinder or liner is mounted in each hole in the block. These liners are press-fitted, in contact with the block wall, so that they can be refrigerated.

- Wet liner block: The liners are thick-walled and in direct contact with the coolant, which constitutes the true cylinder. They are easily removable and are equipped with sealing gaskets to prevent liquid from passing to the postman.

Engine cylinder head

The cylinder head is fixed by screws or studs on the upper plane of the block. The cylinder head serves as a watertight cover for the cylinders, since it houses all or part of the combustion chamber, except in the case that it is formed in the piston head.

The valves are installed, among other elements, in the 4-stroke engine, with the mechanisms to actuate them; ignition and injection elements, intake and exhaust manifolds, etc. In the cylinder head, the coolant chambers are also machined.

Cylinder heads are generally made of aluminum alloy, a material with a low specific weight and good thermal conductivity, which allows heat to be quickly evacuated. The cylinder heads for the 2-stroke engine (small cylinder motorcycles) are simpler, since they do not have a distribution, and many are air-cooled.

To ensure a perfect seal between the cylinder head and the cylinder block and taking into account that it has to withstand high pressures and temperatures, a gasket, called cylinder head gasket, is made between the two elements, made of synthetic fibers to replace asbestos, very negative for health.

Sump

The crankcase is the container that contains the lubrication oil from the heat engine. It is mounted on the bottom of the block using screws and with the interposition of a gasket to facilitate sealing. Normally it is made of sheet steel, although it can also be made of aluminum alloy, due to the good thermal conductivity of this metal and the reduction in the noise level of the motor.

Inside the crankcase there are partitions to stop the movement of oil during the movement of the vehicle. At the bottom, a screw cap is added to drain the oil.

What are the moving elements of a heat engine?

Piston

The piston is the mobile element that moves inside the cylinder, with an alternative rectilinear movement. This movement is given, at the moment of the explosion, by the force of the gases and, during other times, by the connecting rod. It consists of two parts: the head and the skirt. The head receives the pressure caused by the explosion and works at very high temperatures (from 300 ºC to 400 ºC). It has grooves where the segments that ensure sealing are housed. Normally it is made of aluminum with alloys of copper, silicon and nickel to harden it.

The piston is attached to the connecting rod through the bolt, allowing an oscillating movement between the two elements. The bolt is made of cemented steel, a material of great hardness and toughness, and in the form of a hollow cylinder to lighten its weight and, therefore, to reduce inertia.

Segments

They are elastic rings, located in a variable number on the grooves made in the piston head.

They fulfill the following functions:

- Ensure the tightness and lubrication of the cylinder.

- Evacuate heat to the cylinder.

- Prevent oil from passing into the combustion chamber.

There are two types: compression and ontaje.

Compression segments: Generally two are mounted, the fire one and the sealing one:

- Fire segment: It is mounted on the highest part of the piston head and is subjected to very harsh working conditions due to the pressures and high temperatures to which it is exposed. To increase its resistance, it is usually coated with chrome.

- Watertight segment: It is located after the fire segment and is usually conical. The largest segment is below. It is subjected to less severe conditions than the fire segment.

Ointment segment: It is located after the sealing segment and has on the periphery a series of

Slots that allow the oil deposited on the cylinder walls to be collected during displacement

From the piston and send it into the piston to lubricate the bolt.

White

The connecting rod transmits to the crankshaft the force with which the explosion of gases pushes the piston. At the same time, it is part of the set that transforms the alternative linear movement into rotary. It is generally made of carbon steel alloy with chromium, manganese or molybdenum.

It consists of three parts: head, body and foot. The head is the part that is attached to the crankshaft, through the interposition of the connecting rod semi-bearings, also called antifriction. The body has a double T or H profile; and it is subjected to great tensile, compression and bending stresses, and the upper part, called the connecting rod foot, constitutes the union with the piston through the bolt and with the interposition of a bronze bearing.

Crankshaft

The crankshaft collects the forces originated during the explosion and converts, through the connecting rod, the reciprocating linear movement of the piston into a rotary movement. It transmits the movement and the driving force to the transmission elements that are coupled to it. It is subjected to torsional and bending stresses and has a strong and very resistant structure. Crankshafts, which can be obtained through casting or forging processes, are made of steel with alloys of Cr, Ni, Mo, etc.

The crankshaft consists of supports, usually five for an in-line four-cylinder engine, which are attached to the block bed. It also has elbows called trunnions where the connecting rods are fastened. In the extension of each elbow are the counterweights, which serve to balance the crankshaft. At one end of the crankshaft the timing pinion is mounted and, at the other, the flywheel.

Flywheel

the flywheel has the function of storing kinetic energy to smooth and regularize the rotation of the heat engine. This energy accumulates it in the driving time (explosion) and transfers it during the passive or resistant times (intake, compression and exhaust).

The flywheel is made of gray cast iron and on the periphery, a pressure-fitted door, a toothed crown made of stamped and cemented steel, which is where the vehicle's electric starter motor is fitted. Its weight and dimensions are perfectly calculated for each type of engine.