The electric motor represents one of the most significant advances in the history of electrical engineering. This electrotechnical machine converts electrical energy into mechanical energy, triggering the movement of various devices and machinery. Its operation is essentially the opposite of an electrical generator, which converts mechanical energy into electrical energy.

The concept of the electric motor was consolidated thanks to the fundamental discoveries of pioneers such as Franz Ernst Neumann and James Clerk Maxwell in 1841 and 1873, respectively. These scientists laid the theoretical foundations that allowed the development and practical application of electric motors in various industries and areas of daily life.

Since then, electric motors have revolutionized the way we interact with modern technology, powering a wide range of devices and systems, from household appliances to large-scale industrial machinery. Their versatility and efficiency make them indispensable elements in the era of electrification, contributing to progress and innovation around the world.

Types of electric motors

Electric motors are primarily categorized based on the type of electric current they use:

1. Direct current (DC) motors

DC motors use a DC power source for operation. These motors are widely used in a variety of applications due to their ability to offer precise control of speed and torque.

Within this category, you can find the permanent induction motor, which uses permanent magnets in the rotor, and the controlled induction motor, which allows the speed to be varied in a controlled manner.

2. Alternating current (AC) motors

AC motors are powered by an alternating current source. These motors are extremely common in many industrial and domestic applications due to their simplicity of design and low cost. This type of motor is the most used in electric vehicles, specifically the alternating current synchronous permanent magnet motor.

AC motors can be subdivided into several categories, including:

- Universal motor: This type of motor can operate with both direct current and alternating current. They are characterized by their high speed and their ability to provide high torque.

- Synchronous Motor: In this type of motor, the speed of the rotor is synchronized with the frequency of the supplied alternating current. They are used in applications that require a constant and precise speed, highlighting their use in electric cars.

- Asynchronous motor (Induction): Also known as an induction motor, this type of motor is the most commonly used in industrial and commercial applications due to its low cost and robustness.

In addition to these more traditional classifications, more modern motors have emerged that address specific needs in various applications, such as stepper motors, which are used in precision positioning and control systems, and linear motors, which offer direct linear motion in rotating place.

How does an electric engine work?

The operation of an electric motor varies depending on the type of motor they are part of.

Operation of a direct current motor with permanent induction

The direct current motor is the simplest motor. Going from the outside of the engine to the inside we find:

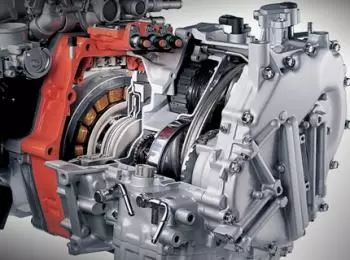

- The casing or crankcase, which has a fixing system to the bench or chassis. In the crankcase there is an assembly called a stator or inductor that is made up of a sheet metal support and some magnets or electromagnets.

- The rotor, which is formed by a core of sheets on an axis that supports everything. The shaft is surrounded by a series of windings that are connected to the collector fins. The electric current is received through the collector's fins. All of this is supported by the bearings at the ends of the crankcase.

- On one side of the shaft is the pulley. The pulley is a toothed crown or coupling that transmits mechanical energy to be used.

When the current is sent through the brushes to the collector, an electric current is passed through the conductors of the coils, which, by the left-hand rule (remember that they are immersed in the stator field), creates a force lateral, and the sum of all of them gives us the torque that makes the rotor or motor assembly rotate. Through the collector, current is given to the appropriate coils so that this pair is as strong as possible. They are the motors that are in devices that are powered by cells or batteries.

DC motor with variable induction and universal alternating current

It is the same as the motor with permanent induction, but in this case what produces the field are coils that work like an electromagnet, and are connected to the rotor in series or parallel. This motor also works with single-phase alternating current. The most common example is the motors of normal household appliances.

asynchronous alternating current electric motor

In an asynchronous motor, there are three groups of windings in the stator. These windings correspond to the three phases of commercial alternating current, and the rotor, instead of the collector, has three rings, which are connected to the rotor windings. This type of electric motor works by the same principle, although due to the displacement between phases, a rotating field is produced, which in a certain way drags the rotor.

A particular case that is widely used is the squirrel cage motor, since it is a very simple motor. In which the thin ones and windings of the rotor are replaced by rods with rings at the ends joining the rods, hence its name.

In asynchronous alternating current motors, the windings can be connected in two ways: Star, when one end of the coils is common and the other connected to each of the phases. The other is in a triangle, when the ends of the coils are connected to each other and in one phase. The exchange of two phases causes reversal of the direction of rotation.

It is the most commonly used engine in the industry, with the star-delta starting system.

Synchronous AC electric motor

The synchronous motor is so called because the speed of rotation is related to the frequency of the supply current. This characteristic is due to the fact that the rotor is supplied with direct current, and is driven by the rotating field produced by the stator coils.

Normally this alternating current motor has a dynamo coupled to the same motor shaft to power the rotor. As the speed varies with frequency and allows the motor torque to be set with minimal consumption, by being coupled to an oscillator its speed can be varied very easily, and therefore it is used in traction systems (AVE-TGV).

Stepper motor

The stepper motor is powered with direct current, and the rotor contains a series of permanent magnets, which are dragged by the stator coils, which are governed by power electronics, determining the angle of rotation, which have proportional control. , are extremely precise in the angle of rotation, or position. These motors are widely used in the motion servos of numerical control machines, or in the read/write motors of computer hard drives.

Motor lineal

Basically, a linear motor is an asynchronous motor that has been developed, so instead of creating a rotating torque, it creates a linear displacement, by the displacement of the phases. These engines are divided into two large groups:

- The slow acceleration ones used in Sky Train, Maglev, etc. transportation.

- OF rapid acceleration used in weapons such as the magnetic cannon and space devices.

Within the same category are electromagnetic induction pumps that allow conductive fluids to circulate. The first tests were done with mercury, then with a mixture of sodium and potassium, in view of the circulation of sodium for cooling in some nuclear power plants.

Efficiency and performance

The efficiency and performance of electric motors are critical aspects that impact their applicability, operating costs and their environmental footprint. The key concepts related to the efficiency and performance of these engines are examined below:

The efficiency and performance of electric motors are critical aspects that impact their applicability, operating costs and their environmental footprint. The key concepts related to the efficiency and performance of these engines are examined below:

- Energy efficiency is defined as the relationship between useful output power and electrical input power, determining the motor's ability to convert electrical energy into mechanical work. Modern motors are designed to achieve high levels of efficiency while reducing energy consumption.

- Despite advances in design, motors still suffer losses , including electrical resistance in the windings (copper losses), hysteresis and eddy currents in magnetic materials, mechanical losses due to friction and inertial loads, as well as losses in bearings. Minimizing these losses is essential to improve efficiency.

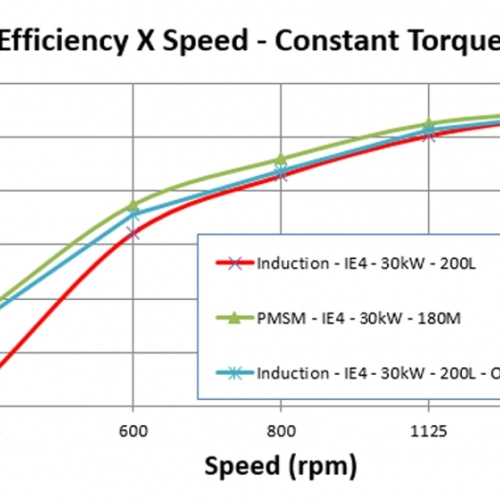

- The efficiency curve shows that motors reach their optimum near their rated load, decreasing in efficiency at lower or higher loads.

Manufacturers are constantly seeking efficiency improvements , such as the use of high-purity conductive materials, aerodynamic design of rotors and stators, and advanced control technologies to optimize performance in real time.

On the other hand, to drive the adoption of more efficient engines, many regions have established regulations and standards that impose minimum efficiency requirements. These regulations, such as energy efficiency ratings from the EPA and the European Commission, encourage the adoption of more efficient technologies, contributing to the reduction of energy consumption and carbon emissions.

History of electric motors

In 1821, following the discovery of the phenomenon of electromagnetism by the Danish chemist Hans Christian Ørsted, the English physicist Michael Faraday built two devices to produce what he called electromagnetic rotation. These devices consist of the continuous circular movement of a magnetic field around a thread. When doing the demonstration, the first description was that of the current electric motor, alternating current, patented in 1887 by the Serbian physicist Nikola Tesla.

In 1822, Peter Barlow created the Barlow wheel. The Barlow wheel is a widget that consists of a metallic disk cut into a star, the extremities of the star are submerged in an air gap containing mercury. The function of mercury is to ensure the passage of current.

The first usable switch was invented in 1832 by William Sturgeon. Later, in 1834, Mr. Thomas Davenport made a direct current motor with this invention. The direct current motor was patented in 1837. The high cost of batteries did not allow these electric motors to have significant initial success.

It is not very clear who the father of asynchronous machines is. This title is disputed by three inventors: Nikola Tesla, Galileo Ferraris and Michail Ossipowitsch.

In 1887 the physicist Nikola Tesla filed a patent on the asynchronous machine. The following year he filed 5 more patents for asynchronous electrical machines. Meanwhile, Galileo Ferraris published treatises on rotating machines.

In 1885 Ferraris published an experiment and subsequently published a theory on the asynchronous motor in April 1888. Finally, in 1889 a German electrician of Russian origin named Michail Ossipowitsch Doliwo-Dobrowolski invented the first three-phase squirrel cage asynchronous motor. . This last electric motor was built industrially starting in 1891.