Direct current electric motors work thanks to the properties of permanent magnets and the magnetic field that is generated when an electric current is circulated through a conductor.

The operation of electric motors is based on an alternating magnetic field. In a direct current motor, therefore, the direction of the magnetic field constantly changes mechanically in the motor with the help of the commutator (collector), or electronically in the case of the so-called brushless electric motor.

The main characteristic of magnets is that they have a south pole (negative) and a north pole (positive). In two different magnets the poles of different signs attract and the poles of the same sign repel.

If we place two magnets aligned and a third magnet in the middle in the perpendicular direction, the natural tendency will be for the attractive force between poles of opposite signs to rotate the third magnet, aligning itself with the other two. The magnetic flux between the magnets produces a force that rotates the third magnet.

If we place two magnets aligned and a third magnet in the middle in the perpendicular direction, the natural tendency will be for the attractive force between poles of opposite signs to rotate the third magnet, aligning itself with the other two. The magnetic flux between the magnets produces a force that rotates the third magnet.

What would we have to do to keep it spinning?

This type of motor, like alternating current motors (induction motors, synchronous motors, etc.), works by electromagnetic induction.

If the polarity of the central magnet could be changed it would continue to rotate looking for the equilibrium position again. But this cannot be done. What can be done is to replace the central magnet with an electromagnet. An electromagnet can change the direction of the electric current that circulates in it and then change the polarity.

What is an electromagnet used for in a direct current motor?

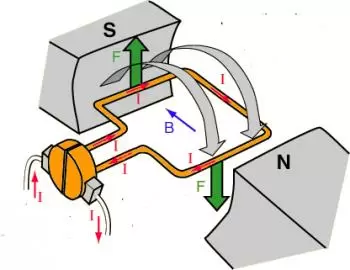

In a direct current (or direct current) motor you need a stator and a rotor inside it.

The stator is called the fixed part where fixed magnets are placed, generating a magnetic field that passes through the rotor, which is the rotating part. In the rotor, a continuous current is circulated back and forth, leaving the center of the rotor in the middle.

When an electric current circulates through a conductor in the middle of a magnetic field, an electromotive force is generated in the conductor that makes it move, and therefore rotate. Once it has reached the equilibrium position, the direction of the current flowing through the conductor is switched and the rotor rotates again seeking the equilibrium position.

The commutator is attached to the rotor shaft. In this way, when the rotor rotates, the commutator alternately alternates the direction of the electric current. In this way, an electric motor converts electrical energy into mechanical energy.

In reality, DC electric motors do not have a single electromagnet, but rather work with several coils that interact with the magnetic field. These coils are activated alternately to obtain better torque throughout the rotation.

What are the ways to run a DC motor?

How the excitation winding is connected with respect to the armature winding largely determines the behavior of the DC motor. The most common realizations are:

Permanent magnet motor

For motors with low powers (<1 kW), permanent magnets are often used for excitation. The advantage of these motors is that they are smaller, lighter, more efficient and more reliable than spiral excitation motors. One disadvantage is that arousal cannot be controlled.

Strange power motor

In motors with extraneous or separate excitation, the excitation coil, which provides the excitation field, is supplied from a separate voltage source, so that it can be regulated independently of the armature voltage.

Serial motor

In the series motor, the excitation coil is in series with the armature winding. This series winding is made up of few turns of thick copper wire.

Shunt motor

In the shunt motor, the excitation coil is parallel to the armature winding. This shunt winding consists of many turns of thin copper wire. The current consumed is divided in two in the motor; most of it flows through the armature winding and only a relatively small part (5% maximum) through the energizing coil.

Compound motor

The compound engine is a combination of the two engines mentioned above; It has a shunt and series excitation winding. The properties of this motor are between those of series and shunt motors.