The 2-stroke engine (or cycle engine) is a type of internal combustion engine that performs the operating cycle in two piston strokes. Active fluid intake must occur during a fraction of the compression stroke, and exhaust must occur during a fraction of the working stroke.

The 2-stroke cycle was conceived to simplify the distribution system, eliminating and reducing the number of valves, and to obtain greater power at the same engine dimensions.

Both the Otto cycle and the diesel cycle can work with two-stroke engines.

Two-stroke gasoline engines are commonly used in engines with small horsepower: motorcycles, lawn mowers, model airplane engines, etc. On the other hand, the diesel version is used in high-power naval applications, up to and including the traction of train machines.

Advantages and disadvantages of 2-stroke engines

With the 2-stroke engine, there is a useful stroke (two linear movements of the piston) for each turn of the crankshaft. In this way, the frequency of the useful stroke and, consequently, the power obtained, is theoretically twice that obtained from a 4-stroke engine of the same displacement.

However, increasing the frequency of the useful stroke tends to cause excessive heating. This heating tends to break the lubricating oil film with the danger of piston and cylinder damage. For this reason, the speed of the 2-stroke engine should, in general, be a little lower than that necessary to perform twice the power.

Another disadvantage of the two-stroke engine is that the fuel consumption is 30% higher compared to a 4-stroke engine with an equivalent displacement.

How does a two-stroke engine work?

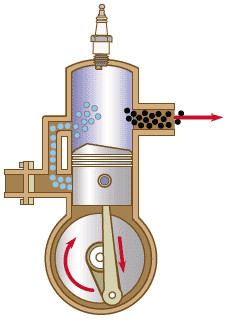

For the proper functioning of the two-stroke engine it is necessary that the active fluid be previously compressed. In this way, the fuel mixture can enter the cylinder and the combustion gases can escape under their own pressure.

In this type of engine, the cycle consists of two strokes:

First stage - Combustion, expansion and exhaust

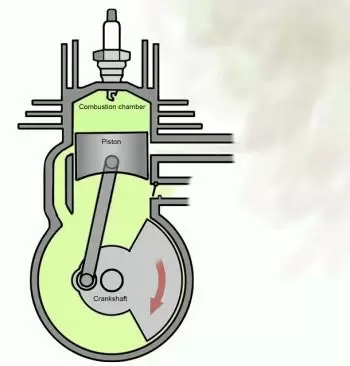

The first time of the two-stroke cycle of heat engines corresponds to the working stroke. In this phase of the cycle, combustion and exhaust occur. As the piston descends to bottom dead center, the burnt gases escape.

The work stroke begins with the ignition and combustion of the fuel in top dead center. Subsequently, the stroke continues with the expansion of the gases throughout the combustion chamber until the piston opens the exhaust port.

The combustion exhaust gases begin to escape due to their still high pressure. During the exit of the gases from the cylinder, a direct current is created towards the outlet.

Immediately afterwards the intake ports are opened. At this time, the pressure exerted by the crankcase pushes the active fluid into the combustion chamber. In addition, the exit of the burned gases generates a current that helps the entrance of the fuel mixture.

In this way, the sweep and admission phase begins, which comprises the rest of the degree.

Second stage - Transfer, Aspiration and Compression

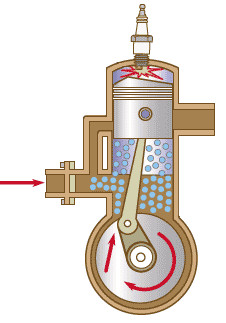

The second cycle time of the two-stroke engine corresponds to the upward movement of the piston returning to top dead center.

The second cycle time of the two-stroke engine corresponds to the upward movement of the piston returning to top dead center.

The first part of this second time is still dedicated to the sweep and admission phase. The second part is dedicated to the compression phase of the fuel mixture.

Before completing the piston stroke, the bottom edge of the piston clears the fluid inlet port in the crankcase. This penetrates as a result of the depression created by the movement of the piston and is then compressed during the next stroke.