A motor or motor is a machine designed to convert a form of energy into mechanical energy. A motor can be classified into a category based on two criteria: the form of energy it accepts to create movement and the type of movement it produces.

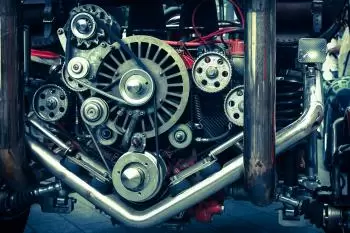

As a general rule, motors have a shaft, which in rotary offset and through mechanical devices such as drive gears. The exceptions are rocket motors and linear motors. Today, combustion engines and electric motors are of utmost importance.

Heat engine or heat engine

In thermal mechanics, a heat engine is a physical or theoretical device capable of exchanging heat and working with the environment or with other physical systems. Heat engines are typically cyclical and are therefore physically described by a thermodynamic cycle. The name of a heat engine is usually that of the associated thermodynamic cycle. They sometimes have names like diesel engine, Otto engine, turbine engine, or steam engines.

Combustion engines are heat engines driven by the heat of a combustion process.

Internal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel (generally fossil fuels) occurs with an oxidant (generally air) in a combustion chamber. In an internal combustion engine, the expansion of high-temperature, high-pressure gases, which are produced by combustion, apply force directly to engine components, such as pistons or turbine blades or a nozzle, and to the moving it a distance generates mechanical work.

External combustion engine

External combustion engines are a type of engine in which fuel is used to heat a working fluid, through which the conversion of thermal energy into mechanical work takes place. The reciprocating steam engine, the steam turbine, and the Stirling engine fall into this category.

An external combustion engine is a heat engine in which an internal working fluid is heated by combustion from an external source, through the engine wall or a heat exchanger. The fluid then, as it expands and acts on the engine mechanism, produces usable motion and work. The fluid is then cooled, compressed, and reused (closed cycle), or (less frequently) discharged, and cold fluid is introduced (open cycle air motor).

The working fluid can be a gas, vapor or a liquid, as in a Stirling engine, a steam engine or an organic liquid respectively. The fluid can be of any composition. Gas is by far the most common, although single-phase liquid is sometimes used. In the case of the steam engine, the fluid changes the phases between liquid and gas.

Breathing air combustion engines

Air-breathing combustion engines are combustion engines that use oxygen in atmospheric air to oxidize ("burn") fuel, rather than carry an oxidant, as in a rocket. Theoretically, this should result in a better specific boost than for rocket engines.

A continuous stream of air flows through the air breathing motor. This air is compressed, mixed with fuel, ignited and expelled as exhaust gas.

Examples of typical air-breathing engines include: reciprocating engine, steam engine, gas turbine, air jet engine, turboprop engine, pulse trigger engine, pulse jet, ramjet, ccramjet, liquid air cycle engine / SABER jet engines.

Non-combustible heat engines

Some engines convert heat from non-combustible processes into mechanical work, for example, a nuclear power plant uses the heat of the nuclear reaction to produce steam and drive a steam engine, or a gas turbine in a rocket engine can be driven by the decomposition of hydrogen peroxide.

Aside from the different power sources, the engine is often designed in much the same way as an internal or external combustion engine. Another group of non-fuel engines includes thermoacoustic heat engines (sometimes called "TA engines") which are thermoacoustic devices that use high amplitude sound waves to pump heat from one place to another, or instead use a heat difference to induce high amplitude sound waves. In general, thermoacoustic motors can be divided into standing wave and traveling wave devices.

Chemically powered non-thermal motor

Non-heat engines are usually powered by a chemical reaction, but they are not heat engines. Examples:

- Molecular motor - motors found in living things.

- Synthetic molecular motor.

Electric motor

The electric motor is a rotating electrical machine that transforms the input electrical energy, applied to the supply terminals, into mechanical energy in the output shown available on the motor shaft. This type of electrical machine is based, similar to what happens in the electrical generator, the electromagnetic forces that interact between a current system and a magnetic field.

Electric motors can be powered by direct current (for example, a battery-powered portable device or motorized vehicle), or by alternating current from a central electrical distribution network.

Smaller motors can be found in electric wristwatches. Medium motors of highly standardized dimensions and characteristics provide mechanical power suitable for industrial uses. The largest electric motors are used for the propulsion of large ships, and for purposes such as pipeline compressors, with ratings of thousands of kilowatts.

Electric motors can be classified by the source of electrical energy, by their internal construction, and by their application.

Physical power engine

Some motors run on kinetic or potential energy, for example, some funiculars, gravity plane transporters, and cable cars have used the energy of moving water or rocks, and some watches have a weight that falls under gravity. Other forms of potential energy include compressed gases (such as air motors), springs (clockwork motors), and rubber bands.

Pneumatic motor

The pneumatic motor, also called a compressed air motor, is a particular type of motor that performs mechanical work by exploiting the expansion of strongly compressed air. Air motors generally convert compressed air into mechanical work through linear or rotary motion.

Linear motion can come from a diaphragm or piston actuator, while rotary motion is supplied by a vane-type air motor or by a piston air motor. Air motors have found widespread success in the hand tool industry and continuous attempts are being made to expand their use to the transportation industry.

Air motors have been around for several centuries in different forms and range in size, from portable motor turbines to powering up to several hundred horsepower. Some types are based on pistons and cylinders, others use turbines. Many compressed air engines improve their performance by heating the incoming air or the engine itself. Air motors are becoming popular in portable equipment, although there are ongoing attempts to expand their use in the transportation industry.

Hydraulic engine

A hydraulic motor is one that derives its power from a pressurized fluid. This type of motor can be used to move heavy loads or produce motion.

Hydraulic motor designs are similar to hydraulic pumps. Some structural differences are associated with the reverse power flow through the hydraulic machine operating in the hydraulic motor mode. Unlike hydraulic pumps, in the hydraulic motor, the working fluid is supplied to the inlet under pressure, and the torque is removed from the shaft at the outlet.