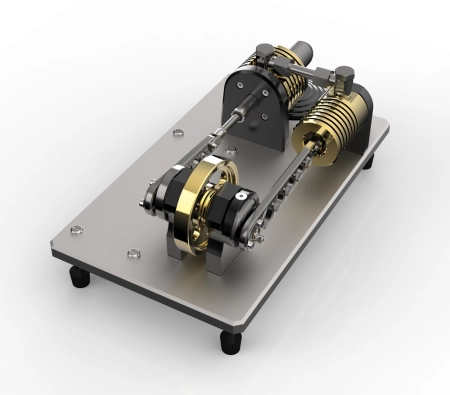

The Stirling engine is an external combustion heat engine. It was originally conceived as an industrial prime mover to compete with the steam engine, but in practice for more than a century it was only used for domestic applications and for low power engines.

The Stirling engine was invented in 1816 by Robert Stirling, a Scottish priest. One of the concerns of the time was the safety of steam engines. Stirling's goal was to achieve an engine less dangerous than the steam engine.

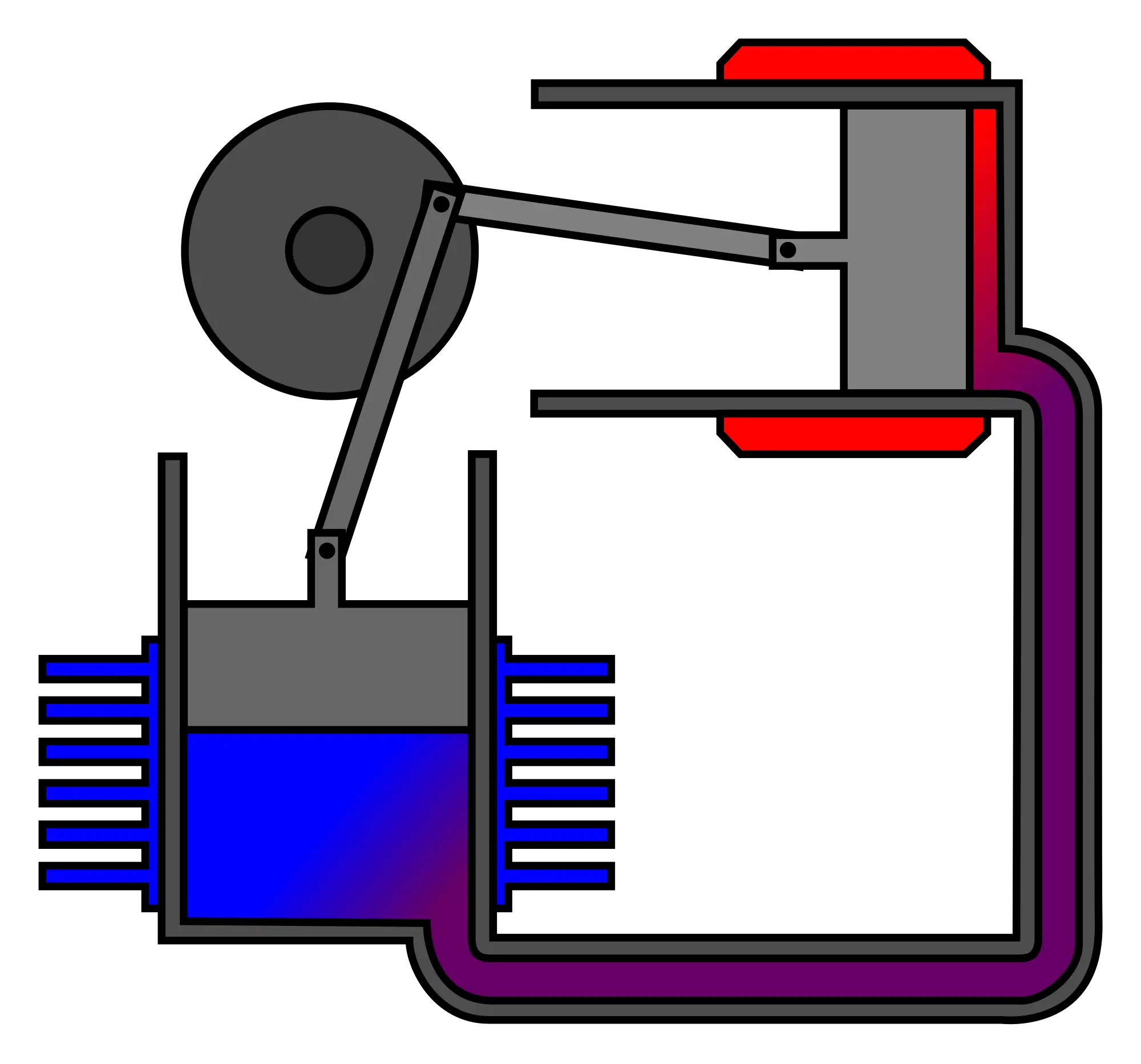

The operation is based on the expansion and contraction of a gas that can be helium, hydrogen, nitrogen or air. This gas is forced to move cyclically from a cold source where it contracts to a hot source where it expands.

This type of machine is considered as a heat engine. It is a thermodynamic engine due to the presence of a temperature gradient between the two thermal sources.

Currently, the development is still under investigation. The fact that it only needs an external heat source gives it great versatility, since this fact gives it the possibility of being able to use many sources of energy for its operation. Examples of energy sources used in this technology are solar thermal energy, fossil fuels such as coal or oil, biomass, geothermal energy and others.

How does a Stirling engine work?

A Stirling engine is a reciprocating engine that operates on a thermodynamically closed regenerative cycle. This cycle is called the Stirling cycle. The main characteristic of this cycle is that it works with cyclic compression and cyclic expansion of the working fluid at different temperature levels.

The Stirling engine is a thermal engine that works through a cycle of compression and expansion of a gas. Two temperature levels are used that cause there to be a net conversion of thermal energy to mechanical energy (mechanical work).

The Stirling engine is a thermal engine that works through a cycle of compression and expansion of a gas. Two temperature levels are used that cause there to be a net conversion of thermal energy to mechanical energy (mechanical work).

The compressed gas exerts a pressure on a piston. The piston is connected to a crankshaft that allows the linear movement of the piston inside the cylinder to be converted into a rotational movement of an axis.

Within the group of thermal engines, like the steam engine, the Stirling engine is classified as an external combustion engine; all heat transfers with the working gas are through the engine wall. On the other hand, in an internal combustion engine, the heat input is made by the combustion of a fuel inside the body of the working fluid.

As is typical in heat engines, the general cycle consists of:

- Compress the gas that is at a lower temperature.

- Heat the gas in a hot spot.

- Expand the hot gas generating mechanical work.

- Cool the gas in a cold source to be able to repeat the Stirling cycle.

What is the efficiency of a Stirling engine?

The efficiency of the process is highly constrained by the efficiency of the Carnot cycle, which depends on the temperature difference between the hot zone and the cold zone. In any case, the Stirling engine is the only one capable of approaching the theoretical maximum efficiency known as the Carnot efficiency.

Carnot cycle

In thermodynamics, the Carnot cycle or Carnot process is an ideal circular process. This cycle consists of two adiabatic processes and two isothermal processes. In the Carnot process, the thermodynamic system performs mechanical work by exchanging heat with two heat reservoirs. The two heat reservoirs have constant but different temperatures.

In the Carnot cycles there are two sources of heat:

- The heater, which is a tank with a higher temperature

- The refrigerator, which is a tank with a lower temperature.

What is the difference between Stirling engine and steam engine?

Unlike a steam engine, the Stirling engine closes a fixed amount of fluid in a permanently gaseous state such as air. In contrast, in the steam engine the working fluid undergoes a phase change from liquid to gas.

The Stirling engine is characterized by its high efficiency compared to steam engines, quieter operation, and easier use of different heat sources.

This compatibility with alternative and renewable energy sources has become increasingly important as the cost of conventional fossil fuels and social sensitivity to climate change have risen. The Stirling engine is currently of interest as the core of micro-combined heat and power units, ie cogeneration, where it is safer and more efficient than steam power.

What is the Stirling engine used for?

This technology is considered to be of great application for regions where there are a large number of dispersed inhabitants, which would be very expensive to reach with an electrical network.

It is to be expected that the manufacturers of Stirling engines will build small units of the same type on a large scale, (with a solar disk) such as, for example, with the capacity to produce about 200 to 400 kWh per month (equipment of approximately 1 to 2 kW of power). ; especially for countries located between the tropics, because in these areas the amount of solar radiation is great throughout the year and in turn is the region where there is more dispersed population.