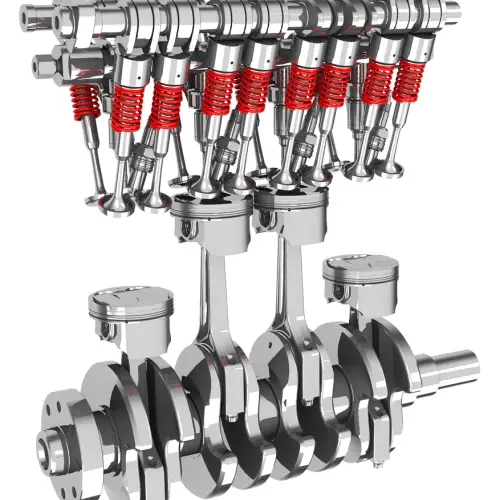

A reciprocating engine uses the linear motion of one or more pistons to convert fluid pressure into mechanical work, usually in the form of rotary motion. This process allows for the production of mechanical energy, which is essential for many industrial and transportation applications. In contrast, rotary machines, such as turbines or the Wankel engine, generate energy directly through the rotary motion of their components.

The reciprocating engine, also known as the piston engine, is a widely recognized and used category of engines. Among these, internal combustion engines are the most common as they are massively used in the manufacture of motor vehicles, from cars to motorcycles and trucks, due to their efficiency and ability to produce a large amount of power.

Although we will focus on thermal reciprocating engines in this article, it is important to note that there are other types of reciprocating engines. These include reciprocating electric motors, which convert electrical energy into linear or rotary motion, and pneumatic or hydraulic motors, which use compressed air or pressurized fluids to generate motion.

Types of reciprocating engine

Reciprocating engines can be classified in many different ways. The main forms of classification are as follows:

Reciprocating engines can be classified in many different ways. The main forms of classification are as follows:

- According to the arrangement of the cylinders in the engine. These can be: in-line if all the cylinders are arranged in a single row, V if the cylinders are arranged in two rows forming a "V", Boxer (opposed) if they are arranged horizontally in two opposite rows and radial if the cylinders are arranged around a central axis, commonly used in aircraft.

- By displacement: Displacement refers to the total volume displaced by all the pistons in the engine during one complete revolution of the crankshaft. It is measured in liters or cubic centimeters (cc).

- According to the compression ratio: The compression ratio is the ratio of the total volume of the cylinder when the piston is at the lowest point to the volume when the piston is at the highest point.

- According to the relationship between bore and stroke: bore is the width of the cylinder, and stroke is the distance the piston travels within the cylinder. Engines can be short stroke, long stroke, or square stroke (bore and stroke are the same).

- According to the number of movements in each cycle: here we distinguish between two-stroke engines , in which the engine completes a power cycle in two piston movements (one revolution of the crankshaft), and the four-stroke engine, which completes a power cycle in four piston movements (two revolutions of the crankshaft).

Classification of reciprocating combustion engines

Combustion engines are mainly divided into two categories:

- Gasoline engine (Otto engine): Uses a spark plug to start the combustion of the air and fuel mixture. Commonly found in cars and motorcycles. Also known as spark ignition engines.

- Diesel engine: Combustion is initiated by compressing the air in the cylinder, which increases the temperature enough to ignite the fuel. Used in heavy vehicles, machinery and generators. Also known as compression ignition engine.

Other types of reciprocating engines

Apart from endothermic engines, there are other types of reciprocating engines that also have important applications:

- Steam Engine: Fundamental in the Industrial Revolution, it uses water vapor to move pistons and generate mechanical energy.

- Stirling engine: Uses the compression and expansion of a gas at different temperatures to produce energy. It is efficient and silent, with applications in renewable energy and refrigeration systems.

Types of spark ignition engines

The main types of spark ignition engines are as follows:

- Gasoline engine: This is the most common version as it is installed in a significant part of cars. It has two fuel supply options: an injector and a carburetor.

- Carburetor engine. A feature is the production of a mixture of fuel and gas in a special mixer - carburetor . Previously, such gasoline engines prevailed; Now, with the development of microprocessors, their field of application is rapidly decreasing.

- Injection engine. A characteristic is the reception of the fuel mixture in the manifold or in the engine cylinders feeding the fuel injection system.

- Gas engines. An engine that burns gaseous hydrocarbons as fuel under normal conditions: mixtures of liquefied gases, compressed natural gases, gas obtained by converting solid fuel into gaseous fuel. The following are used as solid fuel: coal, peat, wood.

These engines are widely used, for example, in small and medium-power power plants, using natural gas as fuel (in the high-power area, gas turbine power units reign).

Types of compression ignition engines

Compression ignition engines, also known as diesel engines, are characterized by the ignition of fuel through the compression of air in the cylinder. Within this category, there are several prominent types.

Two-stroke engine

The two-stroke diesel engine makes a complete cycle in two piston movements and is used in applications where high power and density are required, such as in ships and heavy machinery. This type of engine is simpler in design but can be less efficient and more polluting than four-stroke engines.

Four-stroke engine

On the other hand, the four-stroke diesel engine completes a cycle in four piston movements: intake, compression, combustion and exhaust. This is the most commonly used type in passenger vehicles, trucks and generators due to its greater efficiency and cleanliness compared to two-stroke engines.

Direct injection engine

The direct injection diesel engine injects fuel directly into the combustion chamber, which offers better fuel efficiency and higher power, and is the type used in most modern diesel vehicles. In contrast, the indirect injection diesel engine injects fuel into a pre-combustion chamber before entering the main cylinder, providing smoother combustion but with lower efficiency, and is used in older applications and some small engines.

High speed diesel engines

High-speed diesel engines are designed to operate at high revolutions per minute (RPM) and are used in light commercial vehicles and construction equipment. In contrast, low-speed diesel engines operate at low RPM and are common in marine applications and large-scale generators due to their high durability and fuel efficiency. These various types of diesel engines suit a wide range of needs and applications, each with their specific advantages in terms of efficiency, power, and durability.

History of the reciprocating engine

The history of the reciprocating engine has its roots in the crank mechanism, an early example of converting rotary to reciprocating motion. The earliest hand cranks appeared in China during the Han Dynasty (202 BC–220 AD). Several sawmills in Roman Asia and Byzantine Syria during the 3rd–6th centuries AD employed crank mechanisms that converted the rotary motion of a water wheel into the linear motion of saw blades. In 1206, the Arab engineer Al-Jazari invented the crankshaft, a crucial component in the evolution of reciprocating engines.

Significant development of reciprocating engines occurred in Europe during the 18th century. First came atmospheric engines, followed by steam engines, which revolutionized industry. In the 19th century, the Stirling engine and the internal combustion engine were developed, marking the beginning of a new era in engine technology.

Today, the most common type of reciprocating engine is the internal combustion engine, which runs on gasoline, diesel, liquefied petroleum gas (LPG) or compressed natural gas (CNG). These engines are essential for the propulsion of motor vehicles and the operation of power plants, standing out for their efficiency and versatility in multiple industrial and transportation applications.

Reciprocating Engine Terminology

Not all reciprocating engines correspond to the scheme described, but the essential parts and their operation are similar.

Below we attach a terminology universally used in the field of internal combustion engines or endothermic engines. This terminology is used to indicate some fundamental dimensions and values of this type of engine.

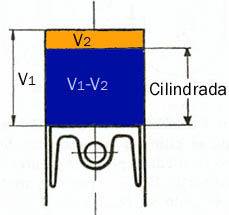

- Top Dead Center (TDC). Position of the piston closest to the cylinder head. Bottom Dead Center (BDC). Position of the piston furthest from the cylinder head.

- Bottom Dead Center (BDC). Position of the piston furthest from the cylinder head.

- Diameter (in English: Bore). Inner diameter of the cylinder. Usually expressed in millimeters (mm).

- Stroke. This is the distance between TDC and BDC, and is equal, with rare exceptions, to twice the radius of the crankshaft crank. It is generally expressed in mm.

- Total cylinder volume (V1). It is the space between the cylinder head and the piston when the latter is at BDC. It is usually expressed in cm3.

- Volume of the combustion chamber (V2). It is located between the cylinder head and the piston when the latter is at TDC. It is usually expressed in cm3.

- Volume displaced by the piston or displacement (V1 - V2). It is generated by the piston in its reciprocating movement from TDC to BDC: It is usually expressed in cm3.

- Volumetric compression ratio (

). This is understood as the ratio between the total volume of the cylinder V1 and the volume of the combustion chamber V2. In general, for short, it is simply called compression ratio:

). This is understood as the ratio between the total volume of the cylinder V1 and the volume of the combustion chamber V2. In general, for short, it is simply called compression ratio: