The universal motor is a type of electric motor that can operate with both direct current and single-phase alternating current, for this reason they are called universal.

These electromechanical devices are used in a variety of applications, from household appliances to power tools. Their versatility and efficiency make them a popular choice in many industries.

In general, they are very simple and economical motors that offer excellent starting torque and can reach very high rotation speeds.

What are Universal Motors?

A universal motor is a type of electric motor that can run on direct current (DC) or alternating current (AC).

Unlike other motors, universal motors are designed to operate with any type of electrical current. This makes them suitable for a wide range of applications, from household appliances to industrial tools.

Parts of a universal engine

Universal motors consist of several key parts that work together to convert electrical energy into mechanical energy. These parts include:

- Rotor : The rotor is the rotating part of the motor and is also known as the armature. It is composed of a shaft and a set of coils or wire windings wound around the shaft. The rotor is the moving part of the motor that rotates when electrical power is applied.

- Stator : The stator (or inductor) is the fixed part of the motor and surrounds the rotor. It contains permanent magnets or wire windings that generate a magnetic field when electrical power is applied. This magnetic field interacts with the rotor's magnetic field, causing the rotor to rotate.

- Commutator: The commutator is a rotary switch mounted on the rotor that reverses the direction of electrical current in the coils of the rotor as it rotates. This ensures that the rotor is always facing the correct direction and continues to rotate.

- Brushes : Brushes are small pieces of conductive material, usually carbon, that are in contact with the commutator. The brushes allow current to flow from the power supply to the rotor through the commutator, generating the rotating motion.

- Casing : The casing is used to hold the parts that make up the stator. Aluminum or steel is normally used for its manufacture.

How does a universal motor work?

When an electrical power supply is applied the current flows through the brushes to the commutator and then to the rotor coils. As current flows through the rotor coils, a magnetic field is created around them due to interaction with the constant magnetic field generated by the stator.

Due to Ampère's law , which states that a conductor carrying electric current experiences a force when immersed in a magnetic field, the rotor coils experience a force that causes them to rotate.

The commutator constantly reverses the direction of current in the rotor coils as they rotate, ensuring that the rotor continues to rotate in the same direction. This results in the continuous rotation of the rotor and therefore the operation of the motor.

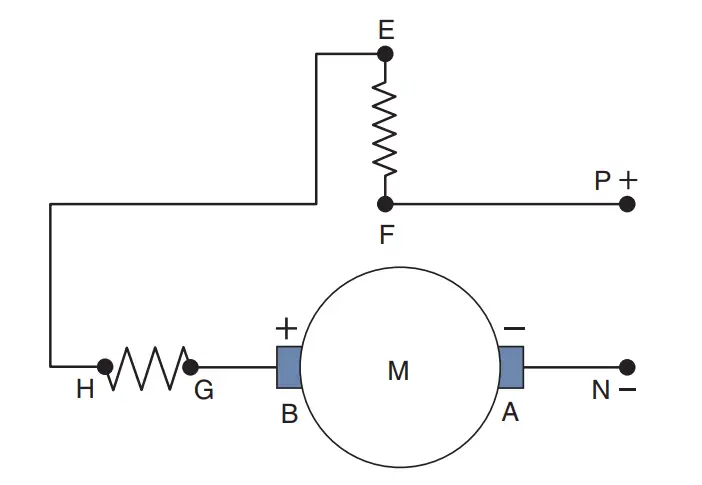

The universal motor diagram is as follows:

Main features

Universal motors have several characteristics that make them stand out in various applications:

High speed

Universal motors are known for their high rotational speed, making them suitable for applications that require fast speeds, such as power tools and household appliances.

The speed is directly proportional to the current, if the direction of the current is reversed, the direction of rotation is reversed.

Unlike asynchronous motors, the rotor of the universal motor rotates at the same speed as the magnetic field of the stator.

High torque

These motors can also generate very high starting torque, making them ideal for starting heavy loads, such as those found in vacuum cleaners or drills.

Variable efficiency

The efficiency of a universal motor can vary depending on load and speed. At light loads, they can be quite efficient, but their efficiency may decrease at heavy loads.

This type of engine is not built for use for long periods of time.

Alternating current (AC) and direct current (DC) compatibility

The ability to operate on both types of electrical current makes them versatile and suitable for a variety of applications and environments.

In alternating current it behaves in a similar way to a direct current series motor and the power is less than when it does it in direct current.

Simplicity

The electrical circuit is very simple, it has only one path for the passage of current, because the circuit is connected in series.

Types of universal engines

Although all universal motors share fundamental characteristics, there are different types depending on their design and specific applications.

Some of the most common types include:

Universal motors series

These motors have a series design in which the rotor and stator are connected in series. They are suitable for applications requiring high torque and variable speeds, such as power tools.

Compound Universal Engines

Compound motors combine elements of series motors and shunt motors. They have a good balance between speed and torque and are used in applications such as fans and sewing machines.

Universal Shunt Motors

These motors have the rotor and stator connected in parallel (shunt). They are ideal for applications that require constant speeds, such as ceiling fans and blenders.

Universal Electronic Commutator Motors

Some modern universal motors use electronic rather than mechanical switches to reverse the direction of current. This improves efficiency and reduces wear on mechanical parts.

Examples of Universal Motor Applications

The use of these alternating current motors is widespread due to the higher starting torque compared to that of induction motors and their high rotation speed, which allows their size and price to be reduced.

The universal motor is, without a doubt, the most widely used electric motor in the household appliance and portable tool industry. It is also used in other applications where high rotational speed is required with weak loads or small resisting forces.

Everyday examples

Some examples of applications where universal motors are used include:

-

Appliances: Used in vacuum cleaners, blenders, hair dryers, and ceiling fans due to their ability to offer variable speeds and high torque.

-

Power Tools: Drills, circular saws, and angle grinders are examples of tools that often incorporate universal motors due to their ability to handle variable loads.

-

Kitchen Appliances: Hand mixers and blenders use universal motors to mix and grind foods with ease.

-

Ceiling Fans: Universal bypass motors are ideal for these devices as they can maintain a constant speed.

-

Sewing Machines: Electric sewing machines often use universal motors due to their ability to provide precise speed and control.

-

Portable Tools: Some portable tools like saber saws and sanders also use universal motors.